Ingredients (2 tables)

2 x 1200 x 800 x 144 mm pine pallet

8 x 300 h x 200 d mm commercial baked beans tin can

1 x 0.25l black egshell paint

2 x found metal net drawers

2 x 2000 x 35 x 35 mm aluminium angle

4 x 1000 x 30 mm aluminium flat

40 x stainless steel rivet

1 x 4000 x 2 d black steel core wire rope

8 x M6 stainless steel eye nut

16 x 2.5 mm aluminium ferrule

16 x 2 mm stainless steel thimble

16 x 19 mm nickel split ring

24 x M6 20 mm black counter sunk socket screws

16 x M6 nuts

120 hours Labour

Recipe

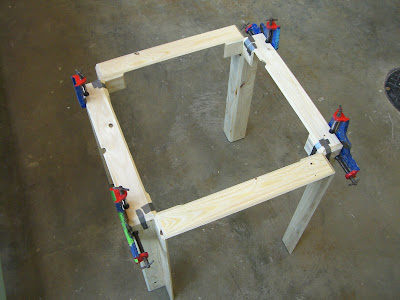

Pallet

Cut wood according to sketch drawing

Miter angles accordingly

Check assembly and glue in stages

Machine sand all over

Paint black detail on inside edge

Tin Cans

Wash and dry cans

Remove top and bottom and retain, cut open sides and stretch out.

Tops and bottoms form one surface, sides form another surface.

Sides

Cut into 25 mm strips along the ripple of the can

Weave and spot weld at edges to hold

Tops

Cut circular discs into squares and spot weld together using offcuts beneath

Sandblast to remove coatings and residue

Pollish with abrasive wheel

Spray 3 thin coats of metal protector

Drill alluminium for fixing

Polish alluminium on polishing wheel

Fix surfaces between aluminium angle and aluminium flat using rivets

Hanging metal drawer

Make up wire loops using ferrules and thimbles

Use nickel split rings at all connections

Bring it all together

Fix surfaces within aluminium frame into wooden frame using counter sunk socket screws and nuts

Fix eyenuts to underside of wooden frame using counter sunk socket screws

Hang metal drawer using wire loops and nickel split rings

Finished!

2 x found metal net drawers

2 x 2000 x 35 x 35 mm aluminium angle

4 x 1000 x 30 mm aluminium flat

40 x stainless steel rivet

1 x 4000 x 2 d black steel core wire rope

8 x M6 stainless steel eye nut

16 x 2.5 mm aluminium ferrule

16 x 2 mm stainless steel thimble

16 x 19 mm nickel split ring

24 x M6 20 mm black counter sunk socket screws

16 x M6 nuts

120 hours Labour

Recipe

Pallet

Cut wood according to sketch drawing

Miter angles accordingly

Check assembly and glue in stages

Machine sand all over

Paint black detail on inside edge

Tin Cans

Wash and dry cans

Remove top and bottom and retain, cut open sides and stretch out.

Tops and bottoms form one surface, sides form another surface.

Sides

Cut into 25 mm strips along the ripple of the can

Weave and spot weld at edges to hold

Tops

Cut circular discs into squares and spot weld together using offcuts beneath

Sandblast to remove coatings and residue

Pollish with abrasive wheel

Spray 3 thin coats of metal protector

Drill alluminium for fixing

Polish alluminium on polishing wheel

Fix surfaces between aluminium angle and aluminium flat using rivets

Hanging metal drawer

Make up wire loops using ferrules and thimbles

Use nickel split rings at all connections

Bring it all together

Fix surfaces within aluminium frame into wooden frame using counter sunk socket screws and nuts

Fix eyenuts to underside of wooden frame using counter sunk socket screws

Hang metal drawer using wire loops and nickel split rings

Finished!